SmartVent System

Traditionally in large commercial kitchens the extraction and fresh air fan motors are operated direct online or with the use of manual speed controllers, with most kitchen extraction systems operating at full output for large periods of time.

During the food prep a large quantity of the cookline equipment is not being used.

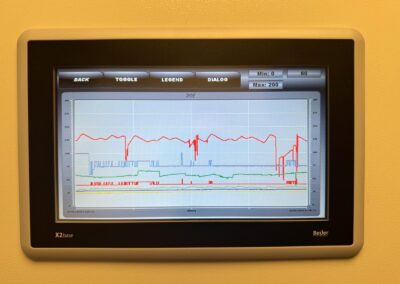

The SmartVent system conserves energy by taking advantage of the affinity laws for centrifugal fans. The system monitors the activity taking place on the cookline using peripheral sensors and provides an appropriate output response to the system fan motors based on the activity on the cookline.

CO2 emissions are reduced dramatically as a result of the reduction in energy consumption.

Further energy savings can be made by reducing the number of air changes associated with the ventilation system if the system has a gas or electric heat battery installed to heat the incoming fresh air supply.

Noise levels in the kitchen area are greatly reduced due to the decrease in fan motor speed which results in a more satisfying working environment.